Full-cycle biomedical engineering

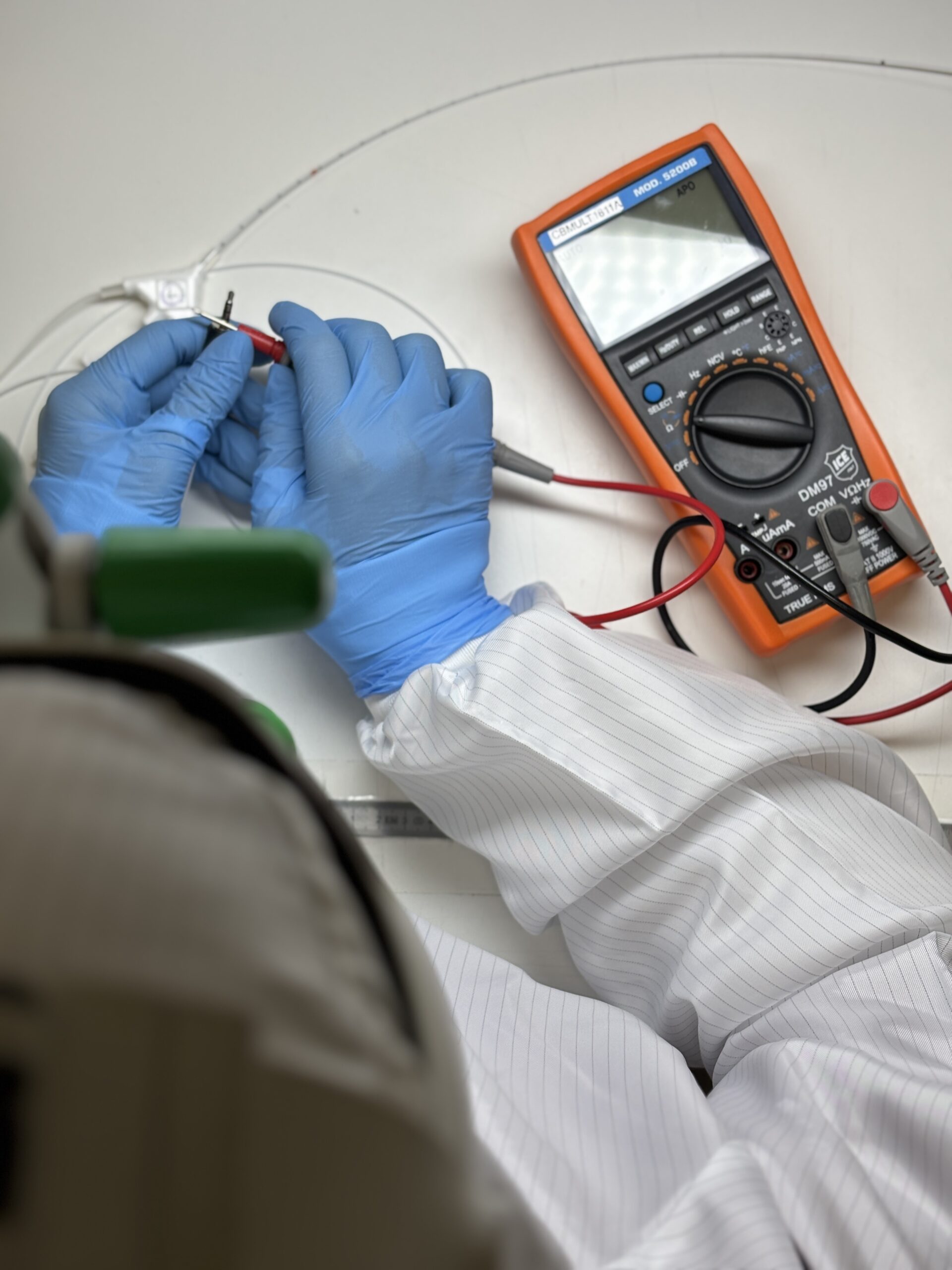

Designing a medical device requires integrated expertise in mechanics, electronics, materials, and industry regulations. MDE offers a structured process that allows for the development of functional, safe, and fully traceable solutions. The operating method involves constant dialogue with the client and the application of internationally recognized design standards. Each phase is documented, verified and subjected to metrological and functional checks.

From concept study to final validation

MDE adopts a co-design approach, where the client is an active participant in the development process. The goal is to reduce industrialization times and ensure full regulatory and functional compliance.

Main stages of the process:

This integrated workflow guarantees optimized timelines, controlled costs, and total traceability.

Development Area

Integration with Research & Development

The R&D division works closely with the Quality department, sharing data and experimental results. Innovations developed in the technical office are quickly translated into engineering solutions applicable to industrial production. The integration between design, research, and production reduces the distance between idea and finished device, increasing the speed of validation and the reliability of the final product.

Design software and tools

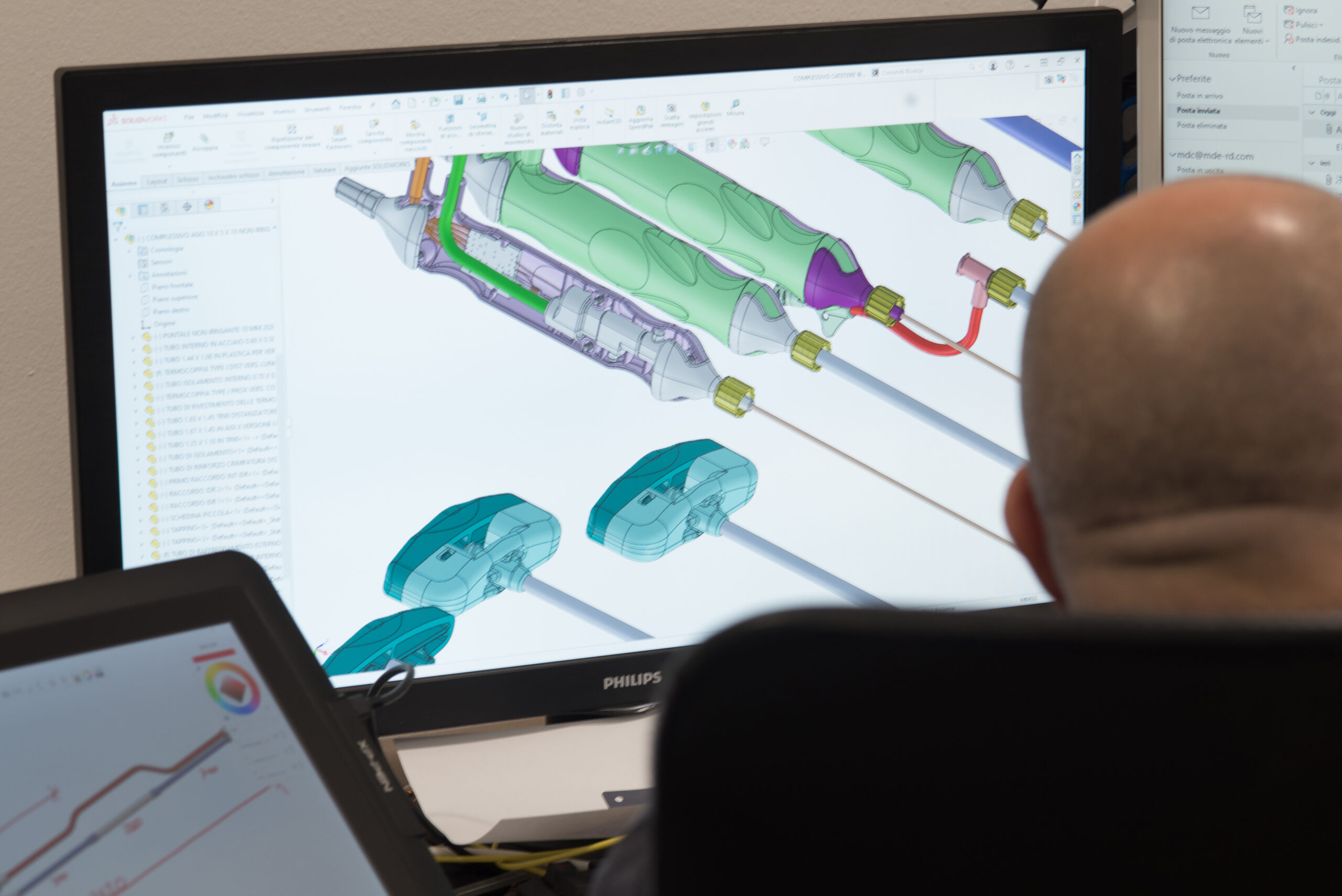

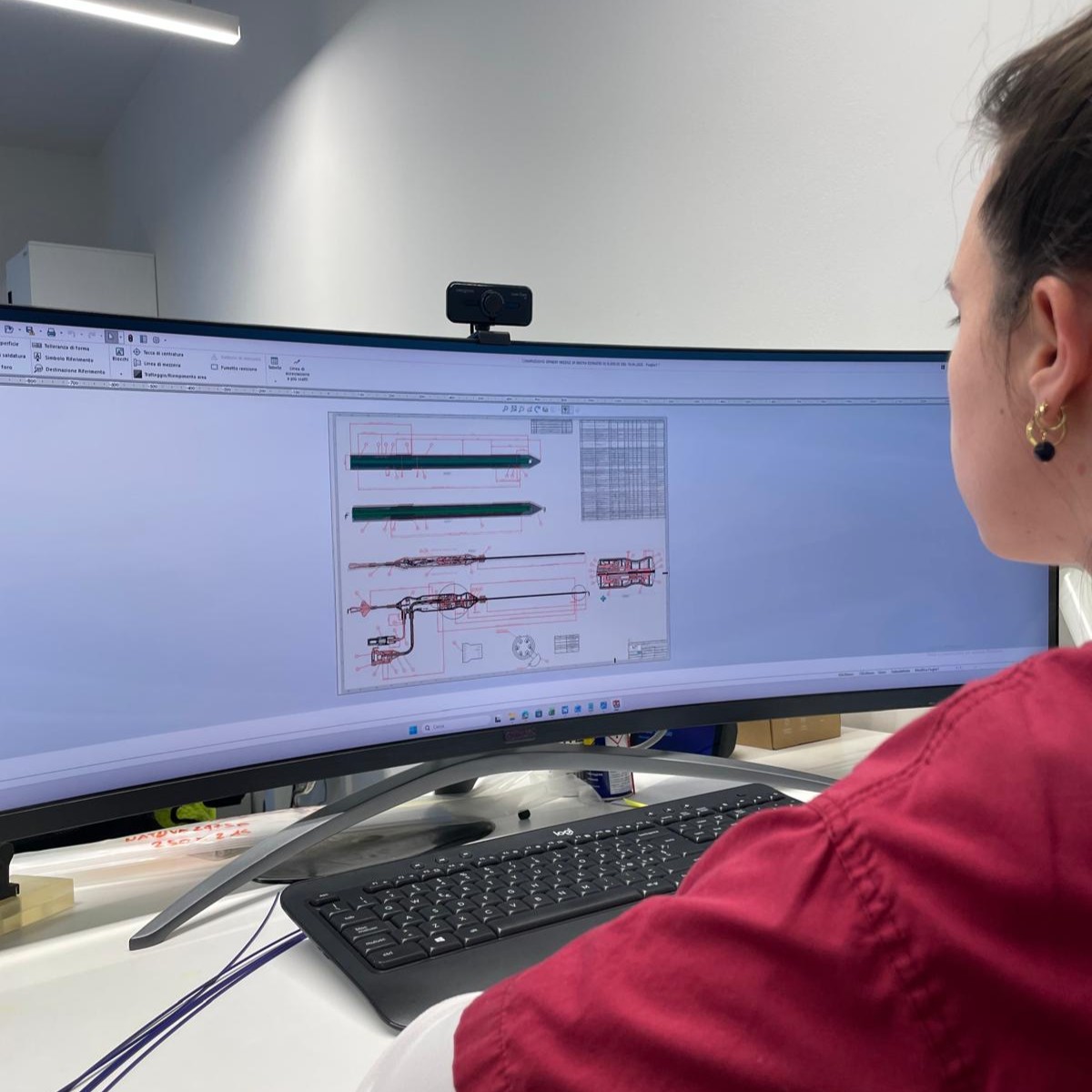

MDE uses 3D CAD platforms and numerical simulation systems to optimize geometries and performance. Digital technologies allow for the advance evaluation of mechanical stress and material flows, improving project efficiency.

Main tools:

Prorotyping production

Prototyping and industrialization

Once the design is validated, MDE moves to the production of prototypes and pre-series, verifying the consistency between the technical drawing and real results. Thanks to the in-house extrusion, molding, and 3D printing lines, prototypes can be quickly tested and optimized before series production. This model accelerates the industrialization of the device and reduces revision cycles.

All our Technologies

MDE prepares all the documentation necessary for the regulatory compliance of the devices:

Every project is managed in compliance with international guidelines for medical devices and internal ISO 13485 quality procedures.

FAQ

Yes, we work on both internal projects and customer specifications, in compliance with confidentiality agreements.

Yes, MDE designs and manufactures medical devices in-house, ensuring full traceability and ISO 13485 compliance.

It depends on the complexity of the device: from a few weeks for simple components to several months for complex projects requiring regulatory validation.

Yes, we create functional prototypes and pre-production runs to verify performance and compliance before final production.

We use 3D CAD, FEM, and CFD software for modeling, simulation, and mechanical optimization of components.