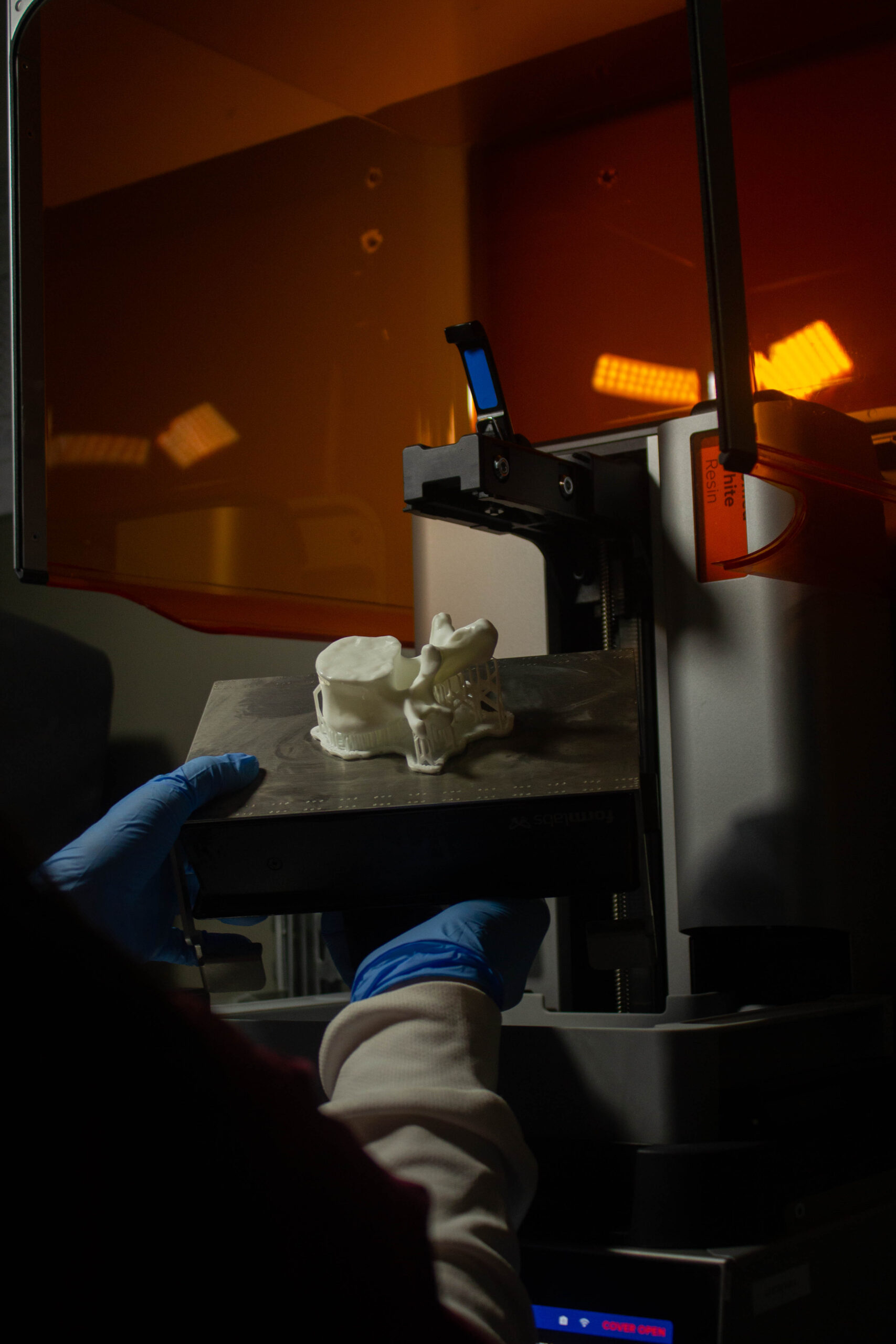

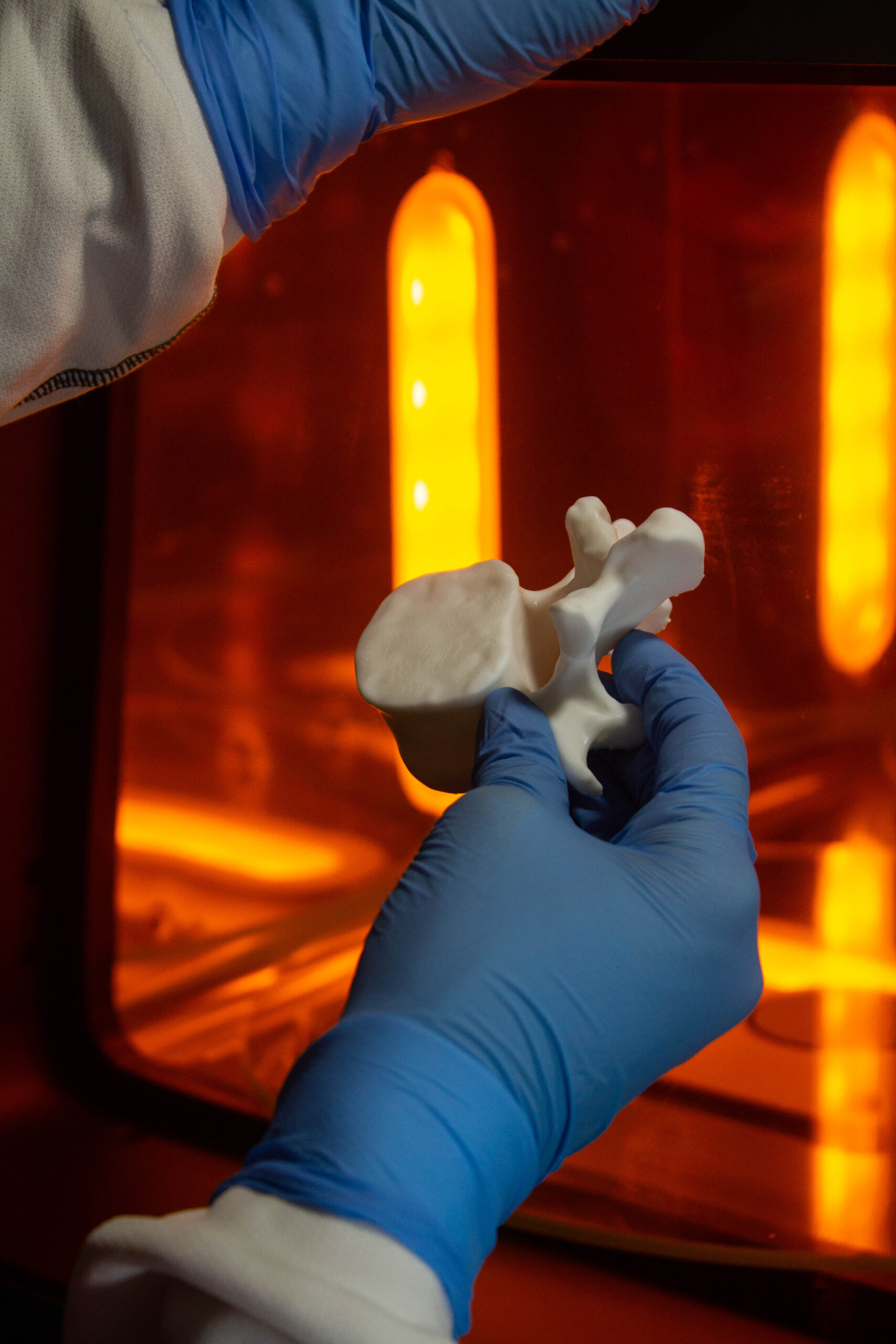

Accelerate Research and Development

3D Printing allows for the rapid and low-cost creation of complex geometries. This is crucial for the R&D division, enabling immediate verification of CAD models and design optimization before industrialization. MDE’s digital prototyping process significantly reduces the device’s Time-to-Market.

Specific Technologies and Materials

We select the most suitable 3D Printing technology based on the required material, resolution, and final application (prototyping, pre-clinical testing, production of tooling components).

3D Printers

3D Printing for Tooling and Equipment

3D Printing is used not only for prototypes but also for the rapid creation of process equipment (tooling), jigs and fixtures, and custom molds for cleanroom and extrusion production. This approach reduces tooling costs and improves production efficiency.

FAQ

FDM, SLA, SLS, and micro-3D printing, chosen based on precision and material requirements.

Yes, each model is dimensionally and functionally verified according to ISO 13485 procedures.

Yes, 3D printing is often used for small series or special components in complex devices.

Yes, each model is dimensionally and functionally verified according to ISO 13485 procedures.