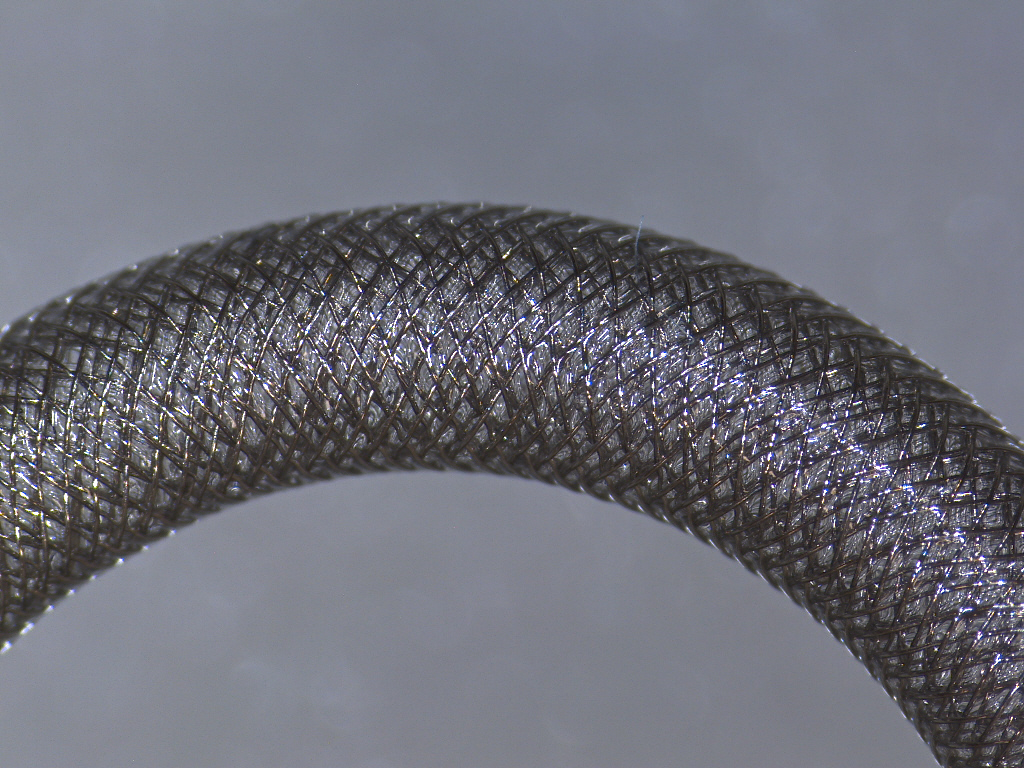

Braiding: Structural Reinforcement

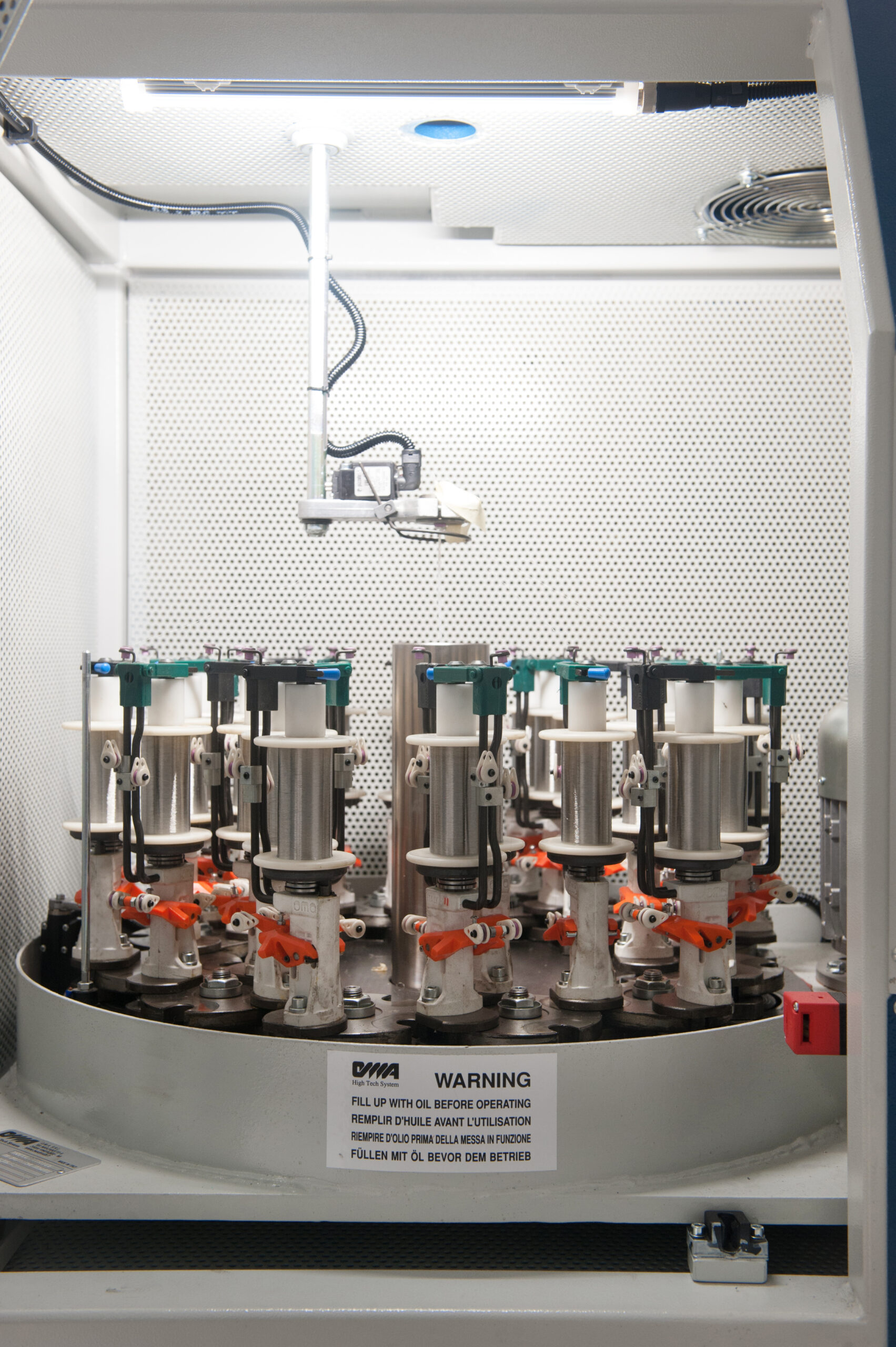

Braiding is a critical process for catheter assembly, as it increases torque resistance, pushability, and controlled flexibility. We use dedicated machinery for the application of reinforcement with polymeric or metallic fibers (such as steel, Nitinol), ensuring precise control of the pick count and tension.

Braiding

We specialize in injection molding and over-molding of micro-components and connectors using medical-grade polymers. This allows for the integration of rigid and flexible parts, reducing assembly steps and improving the reliability of the final device. All phases are validated and traced.

Applications

Materials and Applications

Braiding and Molding technologies are applied to a wide range of medical-grade polymers depending on the structural and biocompatibility requirements of the device.

ISO 8 Cleanrooms and Quality

All Braiding, Molding, and Assembly phases take place in ISO 7 and ISO 8 contamination-controlled environments. This environment is essential to guarantee the purity of the components and compliance with MDR regulations.

FAQ

Stainless steel, aramid, PET, PEEK, and other high-performance materials compatible with cleanroom environments.

It is a braiding technique that allows fibers or metal wires to be inserted inside medical tubing to increase its strength and stability.

It reduces production times, eliminates glue and joints, and improves component cleanliness and sealing.

Yes, we integrate both technologies to create hybrid devices with internal reinforcements and molded parts.